Latest Innovations in Ultrasonic Cleaner Machine Technology

Latest innovations in ultrasonic cleaner machine technology are transforming precision cleaning with improved efficiency, automation, and eco-friendly features.

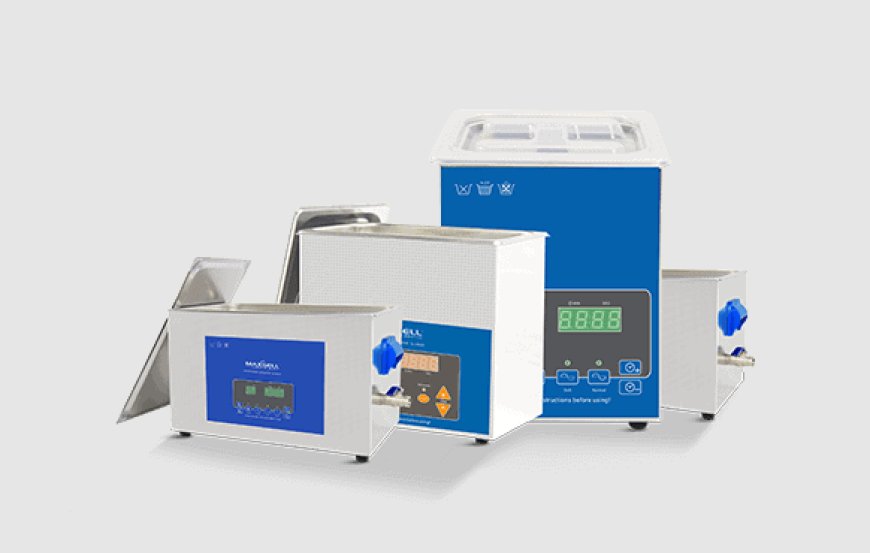

The Ultrasonic Cleaner machine has long been a staple in industries requiring precise and efficient cleaning of delicate or complex components. From medical instruments and laboratory equipment to jewelry and automotive parts, these machines use high-frequency sound waves to remove contaminants that traditional cleaning methods often miss. Recent years have seen remarkable advancements in ultrasonic cleaner technology, with innovations focused on improving efficiency, effectiveness, and environmental sustainability. These new developments are reshaping how industries approach cleaning and maintenance processes.

Advanced Frequency Control and Multi-Frequency Systems

One of the most significant technological breakthroughs in ultrasonic cleaning is the introduction of advanced frequency control and multi-frequency systems. Traditional ultrasonic cleaners typically operate at a single frequency, which limits their effectiveness for different materials and contamination types. Now, newer models come equipped with adjustable frequency settings or can even switch between multiple frequencies within a single cleaning cycle. This innovation allows for more precise and tailored cleaning, especially when working with mixed-material components or complex geometries.

High-frequency ranges, such as 80 kHz or more, are particularly effective for cleaning delicate items like microelectronics or fine jewelry without causing surface damage. Conversely, lower frequencies, such as 25 or 40 kHz, are more aggressive and suited for removing stubborn contaminants like grease or rust. By offering greater flexibility, multi-frequency ultrasonic cleaners enable users to optimize performance based on the specific cleaning task at hand.

Digital Control Systems and Smart Monitoring

Another area of innovation lies in the integration of digital technology and smart controls. Modern ultrasonic cleaner machines now feature touch-screen interfaces, digital timers, and programmable settings that make operation easier and more accurate. These systems allow users to store cleaning cycles, set temperature controls, and even adjust power levels depending on the type of cleaning required.

Smart monitoring features provide real-time feedback on parameters such as temperature, frequency stability, and cavitation intensity. Some advanced models also include diagnostic functions to detect malfunctions early, ensuring long-term reliability and reducing maintenance costs. These intelligent systems enhance operational precision, reduce user error, and contribute to better overall cleaning outcomes.

Eco-Friendly Cleaning with Aqueous Solutions

Environmental concerns are driving innovation in cleaning technologies, and ultrasonic cleaners are no exception. Traditionally, many industrial cleaning processes relied on harsh chemicals, which posed risks to both workers and the environment. Todays ultrasonic cleaner machines are designed to work effectively with water-based or biodegradable cleaning solutions.

These aqueous cleaning agents, when combined with ultrasonic action, provide powerful cleaning performance while minimizing toxic waste and emissions. Some machines are also designed to recycle and filter the cleaning solution, further reducing resource consumption. The result is a greener, safer, and more cost-effective approach to industrial cleaning.

Integration with Automation and Robotics

Automation is rapidly transforming manufacturing and healthcare sectors, and ultrasonic cleaner machines are becoming increasingly compatible with automated systems. Recent innovations include the integration of robotic arms that load and unload items, automated baskets that rotate during cleaning for improved coverage, and programmable conveyors for continuous operation.

These automated solutions not only speed up the cleaning process but also ensure consistency and reduce manual handling. This is particularly useful in high-volume environments such as medical facilities or electronic assembly lines, where cleanliness is critical and downtime must be minimized.

Compact Designs and Portability

As demand grows for on-site or decentralized cleaning solutions, manufacturers are introducing more compact and portable ultrasonic cleaner machines. These smaller units are ideal for use in dental offices, repair shops, and laboratories where space is limited but precision cleaning is still essential. Despite their smaller footprint, many of these machines now offer features that were once limited to larger industrial systems, including digital controls, temperature regulation, and adjustable frequency options.

Conclusion

The field of ultrasonic cleaning is evolving rapidly, driven by innovations in digital control, eco-friendly solutions, automation, and design flexibility. These advancements are not only making the Ultrasonic Cleaner machine more efficient and versatile but also expanding its use across a wider range of industries. As technology continues to progress, ultrasonic cleaners will play an even more critical role in ensuring high standards of cleanliness, safety, and operational efficiency.